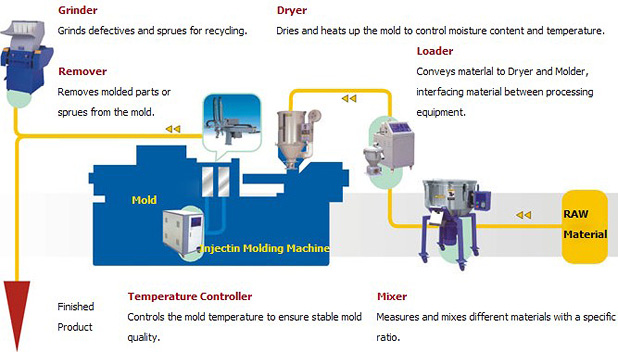

Plastic Molding Process

PRO provides FA system components for plastics processing, ranging from material handling to finishing process.

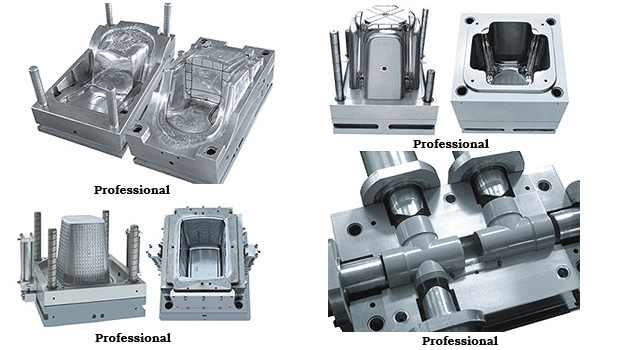

Professional

Professional technician, professional equipment, professional design, professional technical, professional service achieved perfect quality.

We are not only professional on injection molding machine, but also professional on injection mould manufacture.

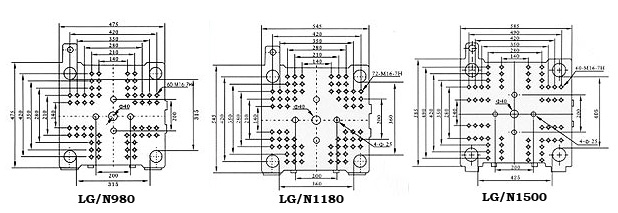

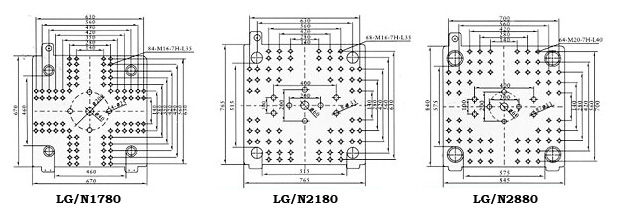

Injection Molding Machines Technical Parameter

|

Description |

- |

LG/N980 |

LG/N1180 |

LG/N1500 |

LG/N1780 |

LG/N2180 |

LG/N2880 |

|

- |

- |

A |

B |

A |

B |

C |

A |

B |

C |

A |

B |

C |

A |

B |

C |

A |

B |

C |

|

Injection Unit |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

Screw Dlameter |

mm |

32 |

36 |

35 |

38 |

42 |

40 |

42 |

45 |

40 |

45 |

50 |

45 |

50 |

55 |

55 |

60 |

65 |

|

Screw L/D Ration |

L/D |

21.5 |

19.8 |

23.9 |

22 |

20.9 |

22.8 |

21.6 |

19.5 |

22.5 |

20 |

18.8 |

22.2 |

20 |

18.2 |

23.1 |

21 |

19.3 |

|

Injection Volume(Theoretical) |

cm3 |

101 |

123 |

154 |

181 |

221 |

238 |

262 |

313 |

273 |

340 |

470 |

406 |

580 |

640 |

712 |

847 |

994.9 |

|

Injection Weight(PS) |

g |

91.5 |

111 |

141 |

165 |

200 |

216 |

238 |

285 |

248 |

310 |

427 |

369 |

515 |

605 |

648 |

779.7 |

905 |

|

Injection Speed |

g/s |

70 |

82 |

80 |

95 |

105 |

90 |

105 |

135 |

108 |

128 |

158 |

120 |

148 |

179 |

210 |

240 |

270 |

|

Plasticizing Capacity |

g/d |

10 |

13 |

12 |

13 |

15.3 |

11 |

12 |

13.5 |

15.8 |

20 |

24.7 |

26.2 |

31.5 |

37 |

28.5 |

31.3 |

34.5 |

|

Injection Pressure |

Mpa |

188 |

148.5 |

219 |

186 |

167 |

195 |

159 |

140 |

202 |

159 |

140 |

216 |

180 |

160.8 |

205 |

168 |

143 |

|

Screw Speed |

r/min |

0-220 |

0-220 |

0-220 |

0-185 |

0-180 |

0-180 |

|

Clamping Unit |

- |

- |

- |

- |

- |

- |

- |

|

Clamp Tonnage |

KN |

980 |

1180 |

1500 |

1680 |

2380 |

2880 |

|

Open Stroke |

mm |

275 |

340 |

380 |

430 |

470 |

540 |

|

Space Between Tie Bars |

mm |

315x315 |

360x360 |

425x405 |

480x480 |

510x510 |

580x580 |

|

Max. Mold Thickness |

mm |

320 |

400 |

450 |

500 |

530 |

600 |

|

Min. Mold Thickness |

mm |

120 |

150 |

170 |

180 |

200 |

220 |

|

Ejector Stroke |

mm |

80 |

100 |

120 |

130 |

135 |

145 |

|

Ejector Force |

KN |

27 |

33 |

33 |

45 |

70 |

75 |

|

Number Of Ejector Pins |

N |

1 |

5 |

5 |

5 |

9 |

9 |

|

Others |

- |

- |

- |

- |

- |

- |

- |

|

Max. Pump Pressure |

Mpa |

16 |

16 |

16 |

16 |

16 |

16 |

|

Pump Motor Power |

KW |

9 |

11-13 |

13-15 |

15-18.5 |

18.5-22 |

22-30 |

|

Heater Powre |

KW |

5.3 |

6.5 |

7.2 |

7.5 |

11.65 |

15 |

|

Machine Dimensions(LxWxH) |

m |

3.5x1.2x1.6 |

4.2x1.25x1.8 |

4.5x1.2x1.7 |

5.1x1.4x1.9 |

5.4x1.5x2 |

6.0x1.6x2.1 |

|

Machine Weight(Approxunat) |

t |

2.7 |

3.3 |

3.7 |

5 |

6.5 |

8.1 |

|

Oil Tank Capacity |

L |

210 |

210 |

230 |

240 |

340 |

570 |

|

Shot Stroke |

mm |

180 |

250 |

290 |

310 |

330 |

420 |

|

Description |

- |

LG/N3680 |

LG/N4200 |

LG/N5800 |

LG/N6580 |

LG/N8000 |

LG/N11800 |

|

-

|

- |

A |

B |

C |

A |

B |

C |

A |

B |

C |

A |

B |

C |

A |

B |

C |

A |

B |

C |

|

Injection Unit |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

Screw Dlameter |

mm |

60 |

65 |

70 |

70 |

75 |

80 |

75 |

82 |

88 |

80 |

90 |

100 |

85 |

95 |

105 |

100 |

110 |

120 |

|

Screw L/D Ration |

L/D |

22.6 |

21.2 |

19.4 |

22 |

20.5 |

19.25 |

22 |

20.1 |

18.8 |

24.7 |

22 |

19.8 |

23.2 |

21.9 |

19.7 |

24.2 |

22 |

20.2 |

|

Injection Volume(Theoretical) |

cm3 |

960 |

1128 |

1306 |

1286 |

1600 |

1750 |

1766 |

2570 |

2720 |

2036 |

3170 |

3230 |

2609 |

4230 |

4520 |

3729 |

6340 |

7210 |

|

Injection Weight(PS) |

g |

873 |

1026 |

1180 |

1170 |

1500 |

1650 |

1607 |

2450 |

2620 |

1853 |

3040 |

3180 |

2374 |

3960 |

4270 |

3393 |

6050 |

6570 |

|

Injection Speed |

g/s |

239 |

275 |

328 |

382 |

438 |

499 |

418 |

461 |

496 |

430 |

545 |

670 |

510 |

547 |

640 |

715 |

804 |

886 |

|

Plasticizing Capacity |

g/d |

31 |

37 |

42.3 |

38.6 |

42 |

47 |

52 |

60 |

65 |

56.5 |

73 |

87 |

67 |

72 |

81 |

91 |

102 |

115 |

|

Injection Pressure |

Mpa |

213 |

183 |

157 |

200 |

174 |

155 |

191 |

160 |

139 |

225 |

179 |

144 |

205 |

170 |

140 |

205 |

170 |

145 |

|

Screw Speed |

r/min |

0-180 |

0-160 |

0-160 |

0-120 |

0-120 |

0-105 |

|

Clamping Unit |

- |

- |

- |

- |

- |

- |

- |

|

Clamp Tonnage |

KN |

3680 |

4200 |

5880 |

6580 |

8000 |

10800 |

|

Open Stroke |

mm |

670 |

720 |

780 |

900 |

940 |

1150 |

|

Space Between Tie Bars |

mm |

660x660 |

720x720 |

800x800 |

890x890 |

950x950 |

1100x1100 |

|

Max. Mold Thickness |

mm |

670 |

810 |

810 |

920 |

940 |

1250 |

|

Min. Mold Thickness |

mm |

240 |

280 |

320 |

360 |

380 |

450 |

|

Ejector Stroke |

mm |

160 |

170 |

210 |

260 |

280 |

320 |

|

Ejector Force |

KN |

62 |

110 |

150 |

175 |

200 |

200 |

|

Number Of Ejector Pins |

N |

13 |

13 |

13 |

17 |

17 |

21 |

|

Others |

- |

- |

- |

- |

- |

- |

- |

|

Max. Pump Pressure |

Mpa |

16 |

16 |

16 |

16 |

16 |

16 |

|

Pump Motor Power |

KW |

37 |

37 |

45 |

30+22 |

30+37 |

45+45 |

|

Heater Powre |

KW |

17.25 |

20 |

32.85 |

47 |

46.5 |

58 |

|

Machine Dimensions(LxWxH) |

m |

6.3x1.9x2.4 |

7x1.9x2.4 |

8.1x1.95x2.5 |

10x2.3x3.6 |

9.9x2.3x2.5 |

12.6x2.9x3..3 |

|

Machine Weight(Approxunat) |

t |

12 |

14.2 |

22 |

34 |

38.5 |

60 |

|

Oil Tank Capacity |

L |

620 |

950 |

1000 |

1405 |

1700 |

2300 |

|

Shot Stroke |

mm |

450 |

480 |

500 |

550 |

600 |

750 |

All above data and specification are subject to change without inform.

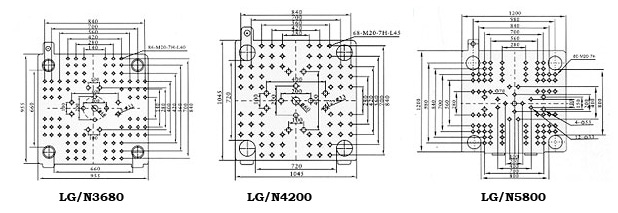

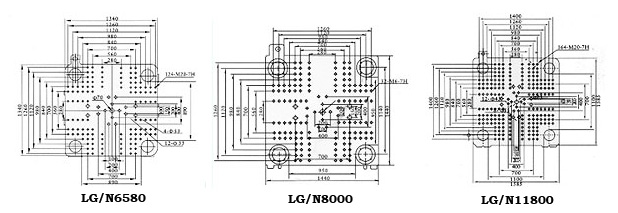

Platen Dimensions

All above data and specification are subject to change without inform.

Theoretical shot volume = (barel cross section) x (screw stroke)

The injection shot weight should be 91% of the theoretical shot volume for polystyrene(ps)